Amplify Your Leadership Voice Worldwide

Join 7,000+ industry leaders sharing insights with millions of professionals globally

Email us: corporate@theceo.in Call Now: 011-4121-9292

Copyright © 2024 The CEO Magazine. All Right Reserved.

Join 7,000+ industry leaders sharing insights with millions of professionals globally

Industry experts like myself are witnessing a significant transformation across various manufacturing sectors. Emerging technologies are reshaping processes, while global supply chain challenges are pressing for adaptation and innovation. As you navigate this landscape, it’s vital to understand the opportunities for growth and the potential roadblocks that lie ahead. Together, we will explore the trends shaping the future, the challenges you might face, and how to leverage new opportunities to thrive in your specific sector.

Your awareness of current trends in industry-specific manufacturing can significantly enhance your competitive edge. As sectors evolve, it’s vital to adapt to innovations and shifts that can redefine production processes. Some of the most notable trends include increased automation, the rise of smart manufacturing, and a growing emphasis on sustainable practices. Together, these trends are reshaping the manufacturing landscape, presenting both challenges and opportunities for those engaged in this continuous transformation.

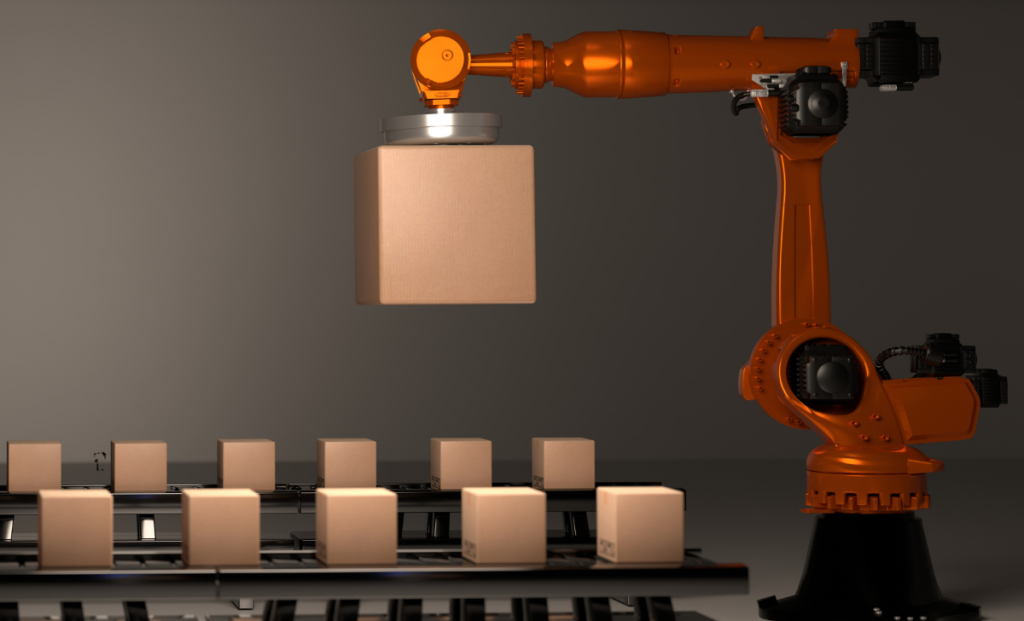

Before diving deeper, let’s explore how technological advancements are influencing industry-specific manufacturing. With the integration of Artificial Intelligence (AI), Internet of Things (IoT), and robotics, manufacturers are witnessing an unprecedented level of efficiency and precision, enabling them to streamline operations and boost productivity.

Above all, sustainability initiatives have become a cornerstone in modern manufacturing practices. Manufacturers are proactively seeking to reduce their environmental impact by adopting greener technologies, implementing waste reduction strategies, and transitioning to renewable energy sources.

Considering these sustainability initiatives, I find that their implementation can lead to substantial improvements in both brand reputation and operational efficiency. By investing in renewable energy and optimizing resource usage, companies not only comply with regulatory standards but also enhance customer loyalty and marketability. However, neglecting sustainability can expose businesses to financial risks and reputational damage in an increasingly eco-conscious market. Hence, embracing innovative sustainability strategies opens new avenues for profit and growth in the competitive manufacturing industry.

Assuming that industry-specific manufacturing will thrive in the future, we must navigate several significant challenges. These sectors face unique obstacles, including supply chain disruptions, workforce shortages, and the rapid pace of technological advancements. Each of these issues can impede growth and innovation, requiring manufacturers to adapt quickly and efficiently to remain competitive.

Above all, supply chain disruptions have been a persistent challenge that I’ve witnessed firsthand. The global events of recent years have highlighted the fragility of supply chains, leading to delays and increased costs. To mitigate these risks, I recommend diversifying suppliers and investing in technology that enhances supply chain visibility.

Below the surface, workforce shortages present significant obstacles for your industry-specific manufacturing initiatives. These shortages can hinder productivity and innovation, limiting the ability to meet customer demands while also increasing operational costs.

With the decline in skilled labor available, manufacturers like you are increasingly confronted with the reality that attracting and retaining talent is more challenging than ever. The gap in skills necessary for modern manufacturing roles not only adversely affects productivity but also hampers growth potential. By embracing training initiatives and collaborating with educational institutions, you can cultivate a skilled workforce that meets your industry’s evolving demands, turning this challenge into a long-term opportunity for success.

One of the most exciting aspects of industry-specific manufacturing sectors is the abundance of opportunities for growth. As markets evolve, businesses can leverage advancements in technology and innovative practices to enhance production capabilities, increase efficiency, and develop new products. By strategically capitalizing on emerging trends and aligning them with your objectives, you can position your organization for sustained success in an increasingly competitive landscape.

Around the globe, emerging markets present substantial opportunities for expansion and growth. As developing economies ramp up infrastructure projects and embrace industrialization, they create a demand for advanced manufacturing solutions. By targeting these regions and tailoring your offerings to meet local needs, you can tap into new customer bases and bolster your market presence.

Innovation in production processes is a key driver for progress in manufacturing. Companies that prioritize advancements in technology, like automation and AI, can significantly increase their productivity and reduce costs. This shift opens up pathways for smaller firms to compete with larger players, making it imperative for you to stay ahead with the latest innovations.

But it’s important to approach innovation with caution. While implementing cutting-edge technologies can lead to enhanced efficiency and productivity, one must also be wary of the associated risks. For instance, an over-reliance on automation might lead to workforce displacement, and the initial costs of advanced systems can strain resources. Therefore, it’s vital for you to weigh the positive impacts, such as increased output and market competitiveness, against potential drawbacks, ensuring a balanced strategy that fosters sustainable growth.

Unlike other industries, manufacturing sectors face unique regulatory challenges that significantly influence operational efficiency and market competitiveness. Compliance with environmental, safety, and quality regulations is necessary, but it can also stifle innovation if not managed effectively. As the regulatory landscape evolves, I find it vital for businesses to adapt quickly and strategically to these shifts, ensuring that they not only comply but also leverage regulations to foster growth and sustainability.

Between evolving government regulations and international standards, manufacturers must navigate a complex landscape of compliance requirements. Staying ahead of these standards is necessary for minimizing risks and enhancing product quality, which ultimately contributes to a stronger brand reputation and customer trust.

Sectors must adapt to changing trade policies that can reshape market dynamics and impact supply chains. This means being proactive about understanding tariffs, trade agreements, and export regulations that can affect both costs and availability of resources.

Even minor shifts in trade policies can have a profound impact on your manufacturing sector. For example, the introduction of new tariffs can increase your production costs and place you at a disadvantage compared to international competitors. Conversely, favorable trade agreements can open up new markets and opportunities for expansion. I urge you to keep a close eye on such changes, as they can create both challenges and opportunities that require swift and informed action to maintain competitiveness.

For anyone involved in manufacturing, examining successful case studies can provide invaluable insights. Here are some notable examples:

Case studies in the automotive manufacturing sector reveal how companies like Toyota have implemented lean production techniques, resulting in a 20% boost in efficiency and a significant reduction in waste. Such approaches not only streamline processes but also enhance overall customer satisfaction by delivering high-quality vehicles more quickly.

After examining successful examples, it is evident that the electronics and technology sector is thriving through innovation. Companies like Samsung have integrated AI into their manufacturing processes, leading to a 30% increase in output while maintaining stringent quality control standards.

The landscape of electronics and technology manufacturing is rapidly evolving. The integration of smart technologies has led to streamlined operations that emphasize automation and data analytics. For instance, firms leveraging AI have dramatically improved their predictive maintenance schedules, reducing equipment downtime by as much as 25%. While the transition to these advanced methods poses challenges, such as the need for workforce training, the benefits—like increased productivity and agility—are substantial. As you navigate this dynamic field, embracing these transformations can position you favorably against your competitors.

Despite the concerns surrounding job displacement, the integration of automation and artificial intelligence (AI) in industry-specific manufacturing sectors promises unprecedented advancements in productivity and innovation. As manufacturers adopt these technologies, they will not only streamline operations but also enable data-driven decision-making, enhancing overall competitiveness in the market.

After implementing automation and AI, I have observed that organizations can significantly improve their operational efficiency through faster production times, reduced waste, and improved quality control. These technologies facilitate continuous monitoring and optimization, allowing manufacturers to respond swiftly to market dynamics.

On one hand, I acknowledge that automation and AI may lead to job displacement in certain roles; on the other hand, they also create opportunities for new job categories and enhanced skill development in the workforce.

But this transformation won’t come without its challenges. While low-skilled positions are at risk of being replaced by machines, there will be a corresponding demand for high-skilled roles focused on operating, managing, and maintaining automation systems. It’s imperative to strike a balance, as certain sectors may encounter labor shortages if workers cannot adapt. Ultimately, the shift toward automation can lead to a more productive workforce, fostering a landscape where skilled professionals are needed more than ever before.

Presently, the future of industry-specific manufacturing sectors is filled with both promising opportunities and notable challenges. As I analyze current trends, I see how technological advancements, sustainability efforts, and shifting consumer demands will shape the landscape. It’s important for you to stay informed and adaptable, as these factors will significantly impact your strategies in this evolving environment. By embracing innovation and addressing challenges proactively, you can position yourself to thrive in the manufacturing sector of tomorrow.

A: The future of industry-specific manufacturing sectors is influenced by several key trends. Firstly, the integration of advanced technologies such as automation, artificial intelligence, and the Internet of Things (IoT) is transforming production processes, leading to increased efficiency and reduced operational costs. Secondly, sustainability is becoming a priority, with companies adopting eco-friendly practices and materials to meet regulatory requirements and consumer expectations. Finally, the shift towards customization is gaining momentum, as manufacturers aim to meet the diverse needs of consumers through flexible production methods that allow for tailored products.

A: While there are numerous opportunities associated with these trends, manufacturing sectors also face significant challenges. One primary challenge is the skills gap in the workforce, as many employees may lack the necessary training to operate new technologies effectively. Additionally, the high initial investment required for advanced manufacturing technologies can deter smaller companies from making the transition. Supply chain disruptions, particularly in the wake of global events like the COVID-19 pandemic, also pose a challenge, making it difficult to maintain consistent production levels and meet market demand.

A: Manufacturers can leverage opportunities by embracing innovation and investing in research and development to stay ahead of the competition. Collaborating with technology providers and educational institutions can help in upskilling the workforce and integrating new technologies smoothly. Moreover, embracing a customer-centric approach by utilizing data analytics to understand consumer preferences can facilitate the creation of more personalized products. Lastly, companies should consider diversifying their supply chains to reduce risk and enhance resilience against future disruptions.

Join industry leaders who have shared their insights with millions of professionals globally.

Join our mailing list to receive the latest news and updates from our team.