Amplify Your Leadership Voice Worldwide

Join 7,000+ industry leaders sharing insights with millions of professionals globally

Email us: corporate@theceo.in Call Now: 011-4121-9292

Copyright © 2024 The CEO Magazine. All Right Reserved.

Join 7,000+ industry leaders sharing insights with millions of professionals globally

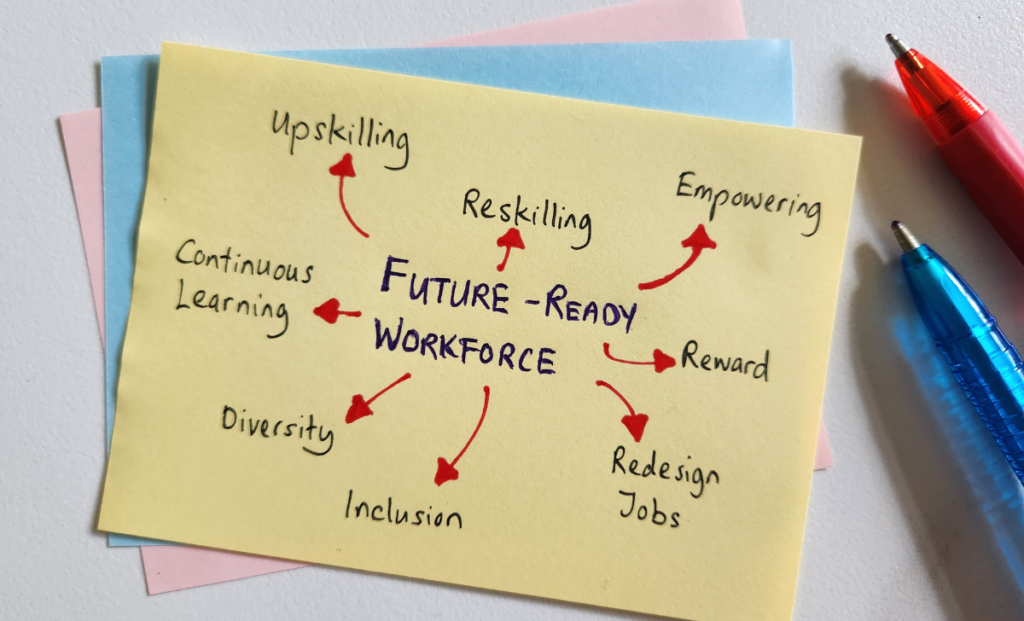

There’s a profound shift occurring in the manufacturing landscape that affects how we work and the skills we need to thrive. As technology evolves, I recognize the necessity of continuous learning and upskilling to stay relevant in this competitive environment. By focusing on the right skills and embracing innovative training methods, you can effectively prepare yourself and your workforce for the future of industry. In this blog post, I’ll explore the necessary strategies for developing a capable workforce ready for the challenges ahead.

The manufacturing sector is evolving rapidly, driven by advancements in technology and shifting market demands. I believe that effective skills development is not just a necessity; it is a pathway to ensure that your workforce remains competent and competitive. Investing in skills development empowers employees, enhances productivity, and fosters innovation, ultimately leading to sustainable growth in the industry.

To thrive in today’s manufacturing landscape, it’s crucial to stay informed about current workforce trends. I observe that automation and digital transformation are reshaping roles and responsibilities. This shift requires a workforce that is adaptable, tech-savvy, and equipped with the latest skills to navigate the changing environment effectively.

At the heart of workforce development lies an effective skills gap analysis. I find that this process helps identify the differences between the skills your employees currently possess and those required to meet industry standards and demands. By pinpointing these gaps, you can tailor your training initiatives to bridge them, ensuring your workforce is future-ready.

Indeed, conducting a skills gap analysis provides invaluable insights into your team’s capabilities and shortcomings. It allows you to focus on specific skill sets that need enhancement while also recognizing the strengths that can be leveraged for innovation. By systematically analyzing these gaps, I can make informed decisions about training programs and development opportunities that align with industry trends. This proactive approach not only mitigates risks associated with workforce shortages but also drives efficiency and competitiveness in the manufacturing sector.

If you want to thrive in the evolving manufacturing landscape, you must focus on acquiring a blend of technical and soft skills. As automation and digital technologies proliferate, the demand for a skilled workforce that can adapt to these changes will only increase. This adaptation will not only ensure individual career growth but also contribute to the overall resilience and competitiveness of the industry.

One of the most significant aspects of your development will be mastering technical skills like programming, data analysis, and machine operation. As the manufacturing sector adopts advanced technologies like robotics and artificial intelligence, having a strong foundation in these areas will differentiate you from your peers and provide a pathway to more advanced roles.

Between highly specialized technical abilities, soft skills such as communication, teamwork, and problem-solving are equally important. These skills facilitate collaboration in multifaceted project environments and help in addressing challenges that cannot solely be fixed through technical expertise.

Even in the most technology-driven settings, the human element remains vital. Skills such as emotional intelligence and adaptability enable you to navigate workplace dynamics and foster an innovative culture. Cultivating these abilities will not only enhance your personal effectiveness but also ensure that you can lead teams and contribute meaningfully to your organization’s success in a rapidly changing manufacturing landscape.

While the manufacturing landscape evolves, adopting comprehensive training and education strategies is imperative for workforce development. These strategies can be tailored to meet the specific needs of the industry while ensuring that workers are equipped with the skills necessary to thrive in a technology-driven environment. By focusing on targeted training programs, we can foster a workforce that not only meets current demands but is also prepared for future challenges.

Across the country, many manufacturers are forging partnerships with educational institutions to create specialized training programs that align with industry standards. These collaborations facilitate a seamless transition from education to employment, enabling students to gain real-world experience and enhancing your workforce’s skill set. Such initiatives not only benefit manufacturers but also provide students with valuable opportunities in high-demand fields.

Beside traditional classroom instruction, on-the-job training programs offer a hands-on approach to skill development. These programs immerse you in the real work environment, allowing you to apply your knowledge and gain practical experience under the guidance of seasoned professionals. This dual approach helps you understand the intricacies of your role and contributes significantly to your growth in the manufacturing sector.

Even though on-the-job training programs can be demanding, they present significant advantages for both employees and employers. By participating in these programs, you develop imperative skills while working directly in your job role. This method not only boosts your confidence but also enhances your productivity. The hands-on experience you gain is invaluable, as you learn to operate complex machinery and adhere to safety protocols in a real-world context. The investment in on-the-job training yields positive results, fostering a more skilled workforce ready to meet the challenges of modern manufacturing.

Once again, technology is reshaping the landscape of workforce development in manufacturing. As automation and advanced technologies take the spotlight, it’s vital for both employees and management to adapt and acquire new skills. The integration of these tools not only enhances productivity but also transforms job roles, creating opportunities for individuals to evolve in their careers. By embracing technology, we can prepare the workforce for the future and ensure the industry continues to thrive.

By optimizing repetitive tasks, automation and robotics are redefining the manufacturing environment. As these technologies become more commonplace, they allow for greater precision and efficiency, enabling you to focus on more complex problem-solving and innovative processes. Understanding how to collaborate with these systems will be necessary for your future success in the industry.

Around the world, digital manufacturing tools are revolutionizing how we design and produce goods. From CAD software to IoT integration, these technologies streamline operations and enhance communication. Your ability to navigate these tools will not only improve operational efficiency but also increase your value in the workforce.

Robotics and automation systems contribute significantly to productivity, yet they can pose risks if not managed carefully. Understanding safety protocols and proper training are imperative to mitigate potential hazards. As you engage with these tools, you’ll find that they facilitate innovative designs and enhance quality control. A proactive approach to adopting digital manufacturing tools ensures you remain competitive, while embracing opportunities for collaboration and continuous improvement within the manufacturing landscape.

Many factors contribute to shaping effective workforce development policies in manufacturing, including the recognition of evolving industry needs, the importance of collaboration among stakeholders, and the promotion of inclusive training programs. As I analyze these elements, I see an opportunity for policymakers to bridge the skills gap by aligning educational curricula with the competencies demanded by the industry. Emphasizing investment in technical skills and continuous learning will be key to preparing a workforce that meets the challenges of the future.

Above all, government initiatives play a significant role in enhancing workforce development in the manufacturing sector. I observe various programs aimed at providing funding for training, incentivizing apprenticeships, and supporting educational partnerships with local industries. These initiatives not only help bridge the skills gap but also create pathways for individuals seeking stable careers in manufacturing.

Standards and certifications are imperative in ensuring that the workforce is equipped with the knowledge and skills necessary for the manufacturing industry. I find that adhering to recognized benchmarks helps professionals demonstrate their expertise and dedication to quality. Furthermore, investing in training that aligns with these standards fosters a culture of excellence within organizations.

At the heart of industry standards and certifications lies the need for consistency, reliability, and safety across manufacturing practices. By pursuing recognized certifications, individuals enhance their resumes while contributing to a more skilled and compliant workforce. Furthermore, aligning training programs with these standards ensures that employees are proficient in current technologies and best practices, ultimately enhancing productivity and innovation. This focus not only benefits employees but also serves the broader goal of driving industry growth and competitiveness.

Despite ongoing challenges, several successful workforce development programs have emerged within the manufacturing sector. These case studies demonstrate the effectiveness of targeted training initiatives:

After exploring various initiatives, I’ve found that local and regional programs play a vital role in workforce development. For instance, community colleges in Michigan partnered with nearby manufacturers, resulting in a 25% increase in relevant skill attainment among graduates. The mentorship schemes in Ohio effectively brought industry veterans into classrooms, creating a supportive environment that fosters learning and growth.

To enhance workforce development strategies, I’ve observed that industry leaders emphasize continuous skill assessment and feedback loops. Programs that adapt to the rapid pace of technological changes stand out as the most successful, ensuring employees remain relevant. Additionally, partnerships with educational institutions can effectively bridge gaps in skill sets.

Also, the significance of collaboration cannot be overstated. Engaging with both local businesses and educational organizations allows programs to offer real-world experience in training. I’ve seen that flexible learning paths cater to diverse learner needs, resulting in a happier, more motivated workforce. Ultimately, these lessons inform not only the development of programs but also adapt to future industry changes, fostering a resilient workforce.

Presently, I see that the future of manufacturing heavily relies on developing skills and enhancing workforce capabilities. As you adapt to the rapid technological advancements, it’s necessary to invest in continuous learning and flexibility. You play a vital role in embracing new tools and approaches, ensuring that you and your team remain competitive in this evolving industry landscape. By prioritizing skills development, you are not only preparing for the demands of tomorrow but also empowering your workforce to thrive in an increasingly automated and innovative environment.

A: As the manufacturing sector evolves, key skills will shift to include advanced technology competencies, such as programming and data analysis, along with traditional skills like precision engineering and quality control. Employees will also need strong problem-solving abilities, teamwork, and adaptability to new processes and tools that integrate automation and smart technologies. Continuous learning and training will be vital as new technologies are introduced, encouraging a culture of lifelong learning to keep up with industry demands.

A: Companies can support workforce development by investing in training programs that focus on both technical and soft skills. Implementing apprenticeship programs allows workers to gain hands-on experience while learning from experienced professionals. Collaborating with educational institutions to create tailored curricula that address specific industry needs helps bridge the skills gap. Additionally, offering mentorship and career advancement opportunities can encourage employee engagement and retention.

A: Technology is reshaping the landscape of manufacturing jobs significantly. Automation and robotics improve efficiency and precision, but they also require a workforce skilled in managing and maintaining these systems. The rise of Industry 4.0, characterized by smart manufacturing and IoT integration, necessitates knowledge in data analytics and cybersecurity. Workers will increasingly need to interact with advanced technologies and, therefore, must develop a solid understanding of these tools to thrive in their roles.

Join industry leaders who have shared their insights with millions of professionals globally.

Join our mailing list to receive the latest news and updates from our team.